Features

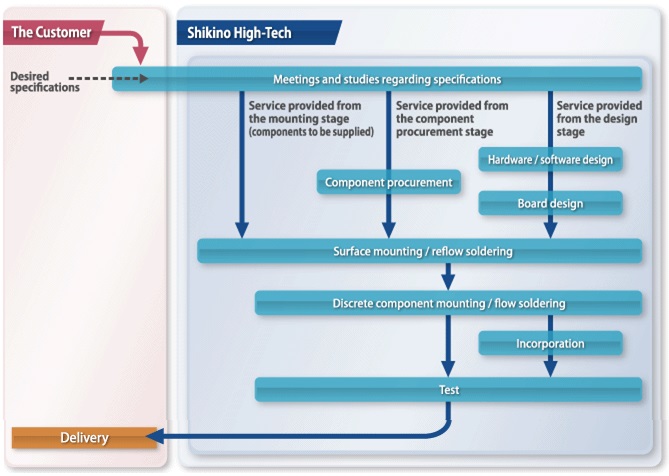

- Support customers' needs with everything from hardware and software design to component procurement, mounting and testing

- Handle all work processes consistently while simultaneously bringing about a reduction in the burden on customers as well as reducing costs and lead times

- Support 508 mm (W) × 620 mm (L) large size circuit boards and mount small-size 0603-type parts

- Support all order lot types from small-quantity large-variety to mass production

- Offer lead-free solder mounting in line with environmental needs

- Acquired the ISO9001 and ISO14001 certification

Extensive experience in the entrusted development of signal generators and control-system microprocessor boards

Support strongly all work types in our customers' development of embedded systems, for everything from development to manufacturing and system verification of hardware (i.e., signal generators, control-system microprocessor boards and other circuit boards and devices) and software (i.e., built-in operating systems and middleware).

|

|

|

|

| General-purpose signal generator for burn-in (main unit) |

General-purpose signal generator for burn-in (PC screen) |

Modular control data conversion board for satellites |

Power supply and signal generator for burn-in |

Surface mount line that supports large size circuit boards and small-quantity large-variety production

- Reduce component procurement cost and offer quick delivery through versatile mounting capabilities

- Support high-density and minute packages

- Prevent incorrect mounting by verification testing using component electrical testing functionality

- Mountable parts - square chips from 1005, BGA, CSP, FC, bare chips and QFP up to 50 mm2

|

|

|

|

| Full view of the line | Solder printer | Mounter | Reflow furnace |

Surface mount line supporting mass production

- Avoid defective mounting via laser recognition that checks for the presence of components immediately prior to mounting

- Support all types of irregular components, high density and minute packages through highly versatile image recognition

- Prevent incorrect mounting by verification testing using component electrical testing functionality

- Mountable parts - square chips from 0603, QFP, BGA, CSP and up to 74 mm2

|

|

|

|

| Full view of the line | Solder printer | Mounter | Reflow furnace |

Lead-free flow-soldering line in response to environmental needs

- A flow soldering bath that uses hot-air pre-heating to bring board temperature to a uniform level and allows soldering under a nitrogen atmosphere

- Point soldering machine that is capable of soldering components to pinpoint specifications without using a jig and achieving cost reduction

|

|

|

|

| Full view of the line | Spray fluxer | Jet solder bath | Point soldering machine |

Main equipment

| Facility name | Manufacturer / model | Maximum board dimensions (L/ W/ H) |

| Automatic paste printing machine | DEK/ Horizon02i | 510×508×6.0 mm |

| Automatic paste printing machine | DEK/ ELA264 | 610×508×6.0 mm |

| Mounter | MYDATA/ MY-15 | 620×750×6.0 mm |

| Mounter | JUKI/ KE-2070・2080 | 460×510×4.0 mm |

| Reflow furnace (hot air on upper surface / far infrared rays on lower surface) | Yamato Works Corporation/ NRY-550PW-7 | |

| Reflow furnace (forced convection) | Nihon Dennetsu Keiki (Vitronics)/ NV-12N | |

| Automatic appearance tester | Shindenshi/ ESV-505L | |

| Automatic jet solder bath (lead-free) | Tamura FA System Corporation/ TNW40-36EF |

Click here for our achivements